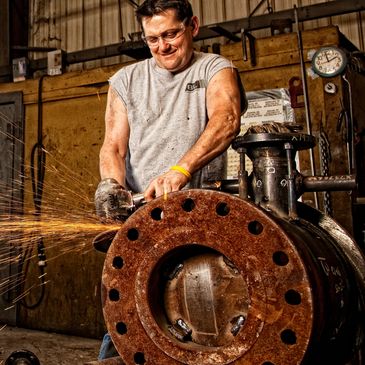

Our Capabilities

Manufacturing Capabilities

Certifications

We are certified to build to:

- ASME Section VIII, Division 1, Pressure Vessels "U" #12,370

- ASME Section 1 Power Boilers "S" #12,371

- NBIC Repairs & Alterations "R" #2,888

- All Tubular Manufacturers Association (TEMA) standards

- API 660 Heat Exchanger Standards

Metallurgies

We can fabricate using the following metallurgies:

- Carbon Steel (P1)

- Stainless Steel

- Austenitic (P8)

- Ferritic (P6)

- Duplex & Super Duplex (P10H)

- Chrome (P4/P5) including API 934 C & E

- Hastelloy

- Inconel/Incoloy

- Monel

- Aluminum

- Copper-Nickel & Brass*

- Titanium*

*Denotes metallurgy used in machined & assembled components only.

Energy Exchanger Company is an industry leader for the highest quality clad & weld overlay heat exchangers.

Size capabilities

Can fabricate heat exchangers up to:

- Maximum Diameter: 120"

- Maximum Length: 75'

- Maximum Weight: 60 tons

- Can go up to 100 tons utilizing outside cranes

- Pressure Testing Maximums

- Hydro: 10,000 PSI

- Air: 105 PSI

Facility capacity:

- Inside Building: 60,000 sq. ft.

- In Yard: 400,000 sq. ft.

- Largest Door 18' W x 21' H

Dowload our brochure

Energy Exchanger Co Brochure (pdf)

DownloadEngineering Capabilities

IN-HOUSE MECHANICAL & THERMAL ENGINEERING

Experienced & Reputable

Have a question for engineering?

Experienced & Reputable

Our Engineering Department has an average of 24 years of experience in shell & tube heat exchangers. Our engineering manager sits on the TEMA technical committee and is the TEMA liason to API, and our thermal engineer chairs the local committee of HTRI.

Fully-degreed

Have a question for engineering?

Experienced & Reputable

Our tremendous engineering staff is a testament to our commitment to quality and to our customers. Each of our engineers has a bachelor degree in engineering from ABET accredited schools to ensure that we offer the most knowledgeable engineering services in our industry.

Have a question for engineering?

Have a question for engineering?

Have a question for engineering?

We love to help. Even if its a question about a future project, give us a call or send us an email.

(918)437-3000

ASME Mechanical Design

Finite Element Analysis (FEA)

Have a question for engineering?

Exceptionally hardworking and incredibly talented, our Mechanical Engineers can design from the very simple to the very complex. Utilizing Hexagon PVElite/CodeCalc software, we can design to customer specificatons & industry standards.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA)

Finite Element Analysis (FEA)

We can perform FEA on nozzles in cylinder bodies or heads in-house by our engineers. We utilize Paulin Research Group NozzlePro software. Just another service we offer to ensure customer satisfaction.

In-House Thermal Rating

Finite Element Analysis (FEA)

Finite Element Analysis (FEA)

Our thermal engineer has over 30 years of experience & 25 years with our company. He utilizes HTRI Xist for thermal rating and is considered an expert in our field. He is a second-generation Thermal Engineer with his father working in the shell and tube industry for decades as well.

Past projects

Energy Exchanger Company

1844 North Garnett Road, Tulsa, OK, USA

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.